A Mass Air Flow (MAF) sensor is a critical component in modern-day automotive engines and other systems where accurate measurement of air intake is essential for proper functioning. The MAF sensor detects the amount of air entering the engine to help calculate the correct air-to-fuel ratio for combustion, ensuring optimal performance and efficiency. Here is an introduction to the Mass Air Flow sensor:

Key Functions of a Mass Air Flow Sensor:

-

Air Intake Measurement:

- The MAF sensor measures the mass of air entering the engine, providing vital data for the engine control unit (ECU) to adjust fuel delivery accordingly.

-

Optimizing Air-Fuel Ratio:

- By accurately measuring the air intake, the MAF sensor helps maintain the ideal air-fuel mixture for efficient combustion and lower emissions.

-

Engine Performance:

- Proper air-fuel ratio control based on MAF sensor data leads to improved engine performance, fuel efficiency, and overall reliability.

-

Emissions Control:

- The MAF sensor is crucial for emission control systems as it ensures that the engine operates within emission regulations by monitoring air intake.

-

Adaptability to Driving Conditions:

- The MAF sensor provides real-time data to adjust fuel injection and other engine parameters based on driving conditions, such as acceleration, deceleration, or idling.

Types of Mass Air Flow Sensors:

-

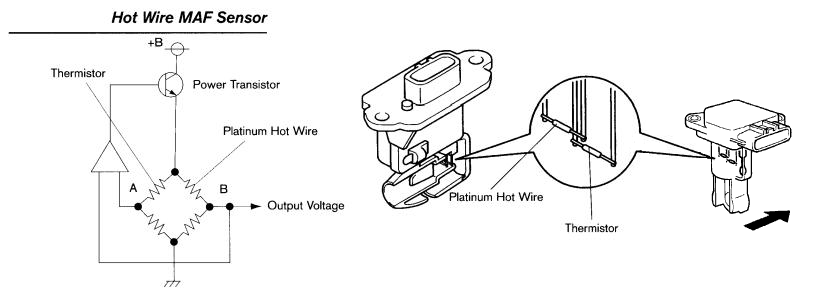

Hot Wire MAF Sensor:

- Uses a heated wire to measure the change in temperature caused by the airflow. The ECU calculates the mass flow rate based on the wire's cooling effect.

-

Vane Meter MAF Sensor:

- Utilizes a movable vane inside the sensor that changes position based on the airflow, converting the displacement into a measurement of air mass.

-

Karo MAF Sensor (Karmen Vortex):

- Relies on the principle of generating vortices by passing airflow around a cylinder. The frequency of these vortices is proportional to the mass flow rate of air.

Importance of the MAF Sensor:

-

Fuel Efficiency: The MAF sensor plays a crucial role in optimizing fuel efficiency by ensuring the engine receives the right amount of air for combustion.

-

Engine Performance: Proper air intake measurement leads to improved engine performance, responsiveness, and longevity.

-

Emissions Control: By maintaining the correct air-fuel ratio, the MAF sensor helps reduce emissions and ensures compliance with environmental regulations.

-

Diagnostic Tool: MAF sensor data is used by technicians to diagnose engine issues related to air intake problems or improper fuel mixture.

Conclusion:

The Mass Air Flow sensor is a fundamental component in modern automotive engines and systems, providing essential data for maintaining optimal air-fuel ratios, engine performance, fuel efficiency, and emissions control. Its accurate measurement of air intake helps ensure the smooth operation and longevity of internal combustion engines in a variety of vehicles and applications.

Mass Air Flow Sensor Structure and principle

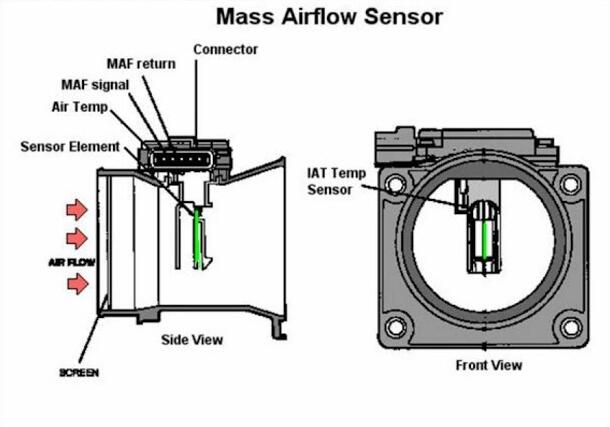

Structure of a Typical Mass Air Flow Sensor:

-

Inlet Tube/Channel:

- The sensor usually contains an inlet through which air flows into the sensor for measurement.

-

Sensing Element:

- The core component responsible for measuring the mass of air passing through the sensor. Different types of MAF sensors use various sensing elements like:

- Hot Wire: A fine wire heated by an electric current whose cooling rate is proportional to the airflow.

- Vane Meter: Utilizes a movable vane that changes position based on airflow, which is then converted into a measurement of air mass.

- Karo (Karmen Vortex): Creates vortices in the air stream for measurement.

- The core component responsible for measuring the mass of air passing through the sensor. Different types of MAF sensors use various sensing elements like:

-

Electronics/Control Unit:

- Handles the signals from the sensing element and processes the data to determine the mass flow rate of air. It communicates with the engine control unit (ECU) to adjust fuel delivery accordingly.

-

Housing/Enclosure:

- Protects the internal components of the MAF sensor and provides a mounting point within the air intake system of the vehicle.

Principle of Operation:

- Hot Wire MAF Sensor:

- Principle: In a hot wire MAF sensor, a fine wire is electrically heated to a constant temperature above the incoming air temperature.

- Operation: As air flows over the hot wire, it cools the wire, altering its electrical resistance. The ECU measures the change in resistance to calculate the mass flow rate of air passing through the sensor.

- Vane Meter MAF Sensor:

- Principle: In a vane meter MAF sensor, airflow deflects a movable vane inside the sensor.

- Operation: The position of the vane changes based on the airflow, and this movement is converted into an electrical signal that corresponds to the mass of air flowing through the sensor.

- Karo (Karmen Vortex) MAF Sensor:

- Principle: The Karo MAF sensor generates vortices by passing airflow around a cylindrical body.

- Operation: The frequency of these vortices is directly proportional to the mass flow rate of the air passing through the sensor. This frequency is measured and used to determine the airflow.

Working of a Mass Air Flow Sensor:

-

Airflow Measurement:

- The sensor measures the volume, velocity, or temperature difference of the air passing through it, depending on its design.

-

Signal Processing:

- The electronic circuitry in the MAF sensor processes the input signals from the sensing element and converts them into a form that the ECU can use for fuel control.

-

ECU Communication:

- The ECU receives the data from the MAF sensor and adjusts the fuel mixture to match the amount of air entering the engine, optimizing combustion efficiency.

-

Engine Control:

- By accurately measuring air intake, the MAF sensor helps the ECU regulate fuel injection, ignition timing, and other engine parameters to maintain optimal performance and emissions control.

The Mass Air Flow sensor's structure and principle of operation vary depending on the type of sensor used (hot wire, vane meter, Karo), but all function to measure the mass of air flow into the engine, providing crucial data for engine control systems to optimize performance and efficiency.

Kármán Vortex Mass Air Flow Sensor:

Principle of Operation:

- Vortex Shedding Principle: The Kármán Vortex MAF sensor operates based on the principle of vortex shedding, coined after the Hungarian-American physicist and engineer Theodore von Kármán.

- Vortex Generation: As the air passes through a bluff body or cylinder in the sensor, it generates alternating vortices on the downstream side of the body.

- Vortex Frequency: The frequency of these vortices is directly proportional to the mass flow rate of the air passing through the sensor.

Structure and Operation:

- Bluff Body: The sensor includes a specially designed bluff body or cylinder placed in the path of the airflow.

- Vortex Detection: Sensors within the device detect the alternating vortices created by the airflow passing around the bluff body.

- Frequency Measurement: The frequency of these vortices is measured by the sensor and used to determine the mass flow rate of the air.

- Electronics: The sensor incorporates electronic circuits to process the vortex frequency data and convert it into a usable signal for the engine control unit (ECU) to adjust fuel delivery.

Benefits of Kármán Vortex MAF Sensor:

- Accurate Measurement: Provides reliable and accurate measurement of air flow rates in the intake system.

- Sturdy Design: Resistant to variations in temperature and pressure, making it suitable for automotive applications.

- Low Maintenance: Generally requires minimal maintenance due to its robust design.

Applications:

- Automotive Industry: Commonly used in automotive engines to measure the mass of incoming air for optimal fuel delivery and engine performance.

- Industrial Applications: Utilized in various industrial systems requiring precise air flow measurements.

Importance in Engine Control:

- Optimizing Fuel Injection: By accurately measuring air intake, the Kármán Vortex MAF sensor allows the ECU to adjust fuel injection rates for optimal combustion efficiency.

- Enhancing Engine Performance: Ensures that the engine receives the right amount of air for combustion, leading to improved performance and fuel efficiency.

- Emissions Control: Helps regulate the air-fuel mixture to minimize emissions and comply with environmental regulations.

The Kármán Vortex Mass Air Flow Sensor is a specialized device that utilizes the principle of vortex shedding to accurately measure the mass flow rate of air entering an engine or system. Its reliable operation and accurate data output make it a critical component in various applications, especially in the automotive industry for engine control and performance optimization.

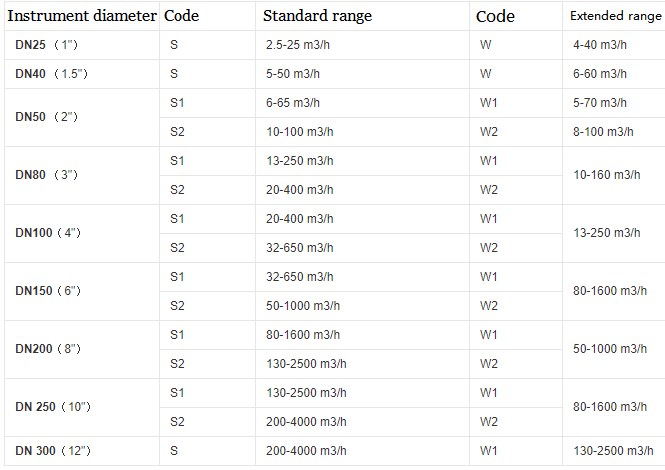

Mass Air Flow Sensor (MAF Sensor) Measuring range

The measuring range of a Mass Air Flow (MAF) sensor refers to the span of airflow rates that the sensor can accurately and reliably measure. The measuring range is essential for ensuring that the sensor can effectively capture the full range of airflows required by the engine for proper operation.

Measuring Range of a MAF Sensor:

-

Minimum Flow Rate: The lower limit of the measuring range specifies the minimum airflow rate that the sensor can accurately measure. This is crucial for idle and low-speed engine operation when the airflow is minimal.

-

Maximum Flow Rate: The upper limit of the measuring range indicates the maximum airflow rate that the sensor can measure without saturating or losing accuracy. This is vital for high-speed engine operation or during heavy load conditions when the airflow is at its peak.

-

Turndown Ratio: The turndown ratio is the ratio of the maximum flow rate to the minimum flow rate that the sensor can measure. It reflects the sensor's versatility in measuring both high and low airflow rates accurately.

Factors Affecting the Measuring Range:

-

Sensor Type: Different types of MAF sensors have varying measuring ranges based on their design and technology (e.g., hot wire, vane meter, Karo).

-

Design Specifications: The physical design and construction of the sensor influence its measuring range capabilities.

-

Calibration: The sensor's calibration and signal processing mechanisms play a crucial role in determining the accuracy and range of airflow rates it can measure.

-

Environmental Conditions: Factors like temperature, pressure, humidity, and air density can impact the sensor's performance and measuring range.

Importance of Measuring Range:

-

Engine Performance: A wide measuring range ensures that the MAF sensor can accurately measure airflow rates across the full spectrum of engine operating conditions, leading to optimized performance.

-

Fuel Efficiency: By accurately measuring airflow, the sensor helps maintain the proper air-to-fuel ratio, enhancing fuel efficiency and reducing emissions.

-

Emissions Control: Ensuring that the MAF sensor can measure airflow within the required range is critical for meeting emission standards and regulations.

-

Diagnostic Capabilities: A broad measuring range allows the sensor to provide valuable data for diagnosing engine issues and optimizing engine performance.

Calibration and Verification:

-

Calibration: MAF sensors are typically calibrated to provide accurate measurements within their specified range. Regular calibration ensures continued accuracy.

-

Verification: Testing and verifying the sensor's measuring range, especially during maintenance or troubleshooting, can help confirm its functionality and reliability.

The measuring range of a Mass Air Flow sensor is a crucial parameter that determines its ability to accurately measure airflow rates across various engine operating conditions. A wide and accurately calibrated measuring range is essential for optimal engine performance, fuel efficiency, emissions control, and diagnostic capabilities.

Ⅴ Frequently asked questions

1. What are the symptoms of a bad mass air flow sensor?

Symptoms of a Faulty Mass Air Flow Sensor

The engine is very hard to start or turn over.

The engine stalls shortly after starting.

The engine hesitates or drags while under load or idle.

Hesitation and jerking during acceleration.

The engine hiccups.

Excessively rich or lean idling.

2. Can you drive with a bad mass air flow sensor?

You can drive your vehicle with a bad mass air flow sensor for a while, but it is not advisable to continue doing so for a long time even if your car can still run and that is because, Ignoring your car MAF sensor problem can escalate beyond just the Mass air flow sensor problem to a more severe engine problem that might even require getting a new engine.

3. What does a mass airflow sensor do?

A mass (air) flow sensor (MAF) is a sensor used to determine the mass flow rate of air entering a fuel-injected internal combustion engine. The air mass information is necessary for the engine control unit (ECU) to balance and deliver the correct fuel mass to the engine.

4. How much does it cost to replace a mass air flow sensor?

To get your mass air flow sensor replaced, you will pay about $300, on average. The labor should cost you around $60, while parts are about $240. The prices vary based on where you go for servicing and what kind of car you have.

5. Why would a car run better with the mass air flow sensor unplugged?

Because either the sensor is reporting incorrect air amount and or air temperature to the ECU. By disconnecting the sensor the ECU switches to limp mode and the car may idle better . Some MAF sensor wires can be cleaned and some cannot as the wires are not easily accessible.

6. Can a dirty mass air flow sensor cause misfire?

Even a dirty MAF sensor can cause a lean code and/or misfire to occur. The engine may be stalling because it isn't getting enough throttle opening. The cause is often a problem in the idle air control system. The first thing to check is the intake vacuum with a vacuum gauge.

7. How long do mass air flow sensors last?

Routine maintenance and air filter replacement can extend the life of your MAF sensor and ensure it continues to work correctly. While the exact timing varies based on where and how much you drive, a good rule to follow is every 10,000 to 12,000 miles.

8. Is it easy to replace MAF sensor?

Mass air flow sensor replacement is very easy to accomplish. One only needs the correct tools and materials for the job. If all goes well, you can have a new MAF sensor in under 15 minutes.

9. Can a mass airflow sensor be cleaned?

We recommend that you clean the MAF sensor every time you change your air filter. Carefully remove the sensor from the air duct and disconnect the electrical connector. Spray 10 to 15 spurts of the mass air flower cleaner onto the wire or plate. Don't scrub the parts; you may break the wire or damage the plate.

10. What makes a MAF sensor go bad?

The sensor element could get contaminated or damaged. For example, in some Mazda Skyactiv engines, a failed mass air flow sensor could cause the engine to crank but not to start. An improperly installed or collapsed air filter can cause the air flow sensor to fail sooner.